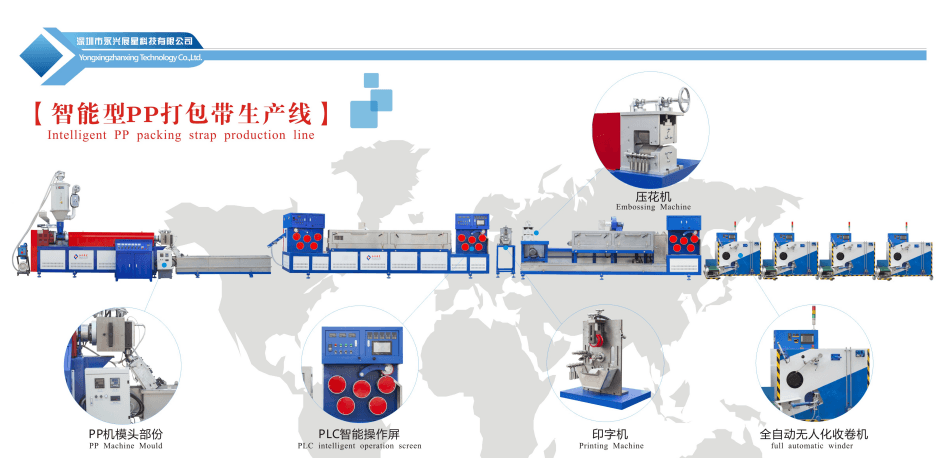

factory low price Reel Winder Machine - 2019 wholesale price Doubling Assemble Winding Machines Before Yarn Twisting Using – Yong Xing Zhan Xing

factory low price Reel Winder Machine - 2019 wholesale price Doubling Assemble Winding Machines Before Yarn Twisting Using – Yong Xing Zhan Xing Detail:

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for 2019 wholesale price Doubling Assemble Winding Machines Before Yarn Twisting Using, We have a professional team for international trade. We can solve the problem you meet. We can provide the products you want. Please feel free to contact us.

We know that we only thrive if we will guarantee our combined cost competiveness and high-quality advantageous at the same time for Cotton Yarn Doubling Machine, Doubling Winder Machine For Tfo Twisting, Doubling Winding Machine, Customer satisfaction is our goal. We’ve been looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and you should feel free to contact us. Browse our online showroom to see what we can do for you personally. And then E-mail us your specifications or inquiries today.

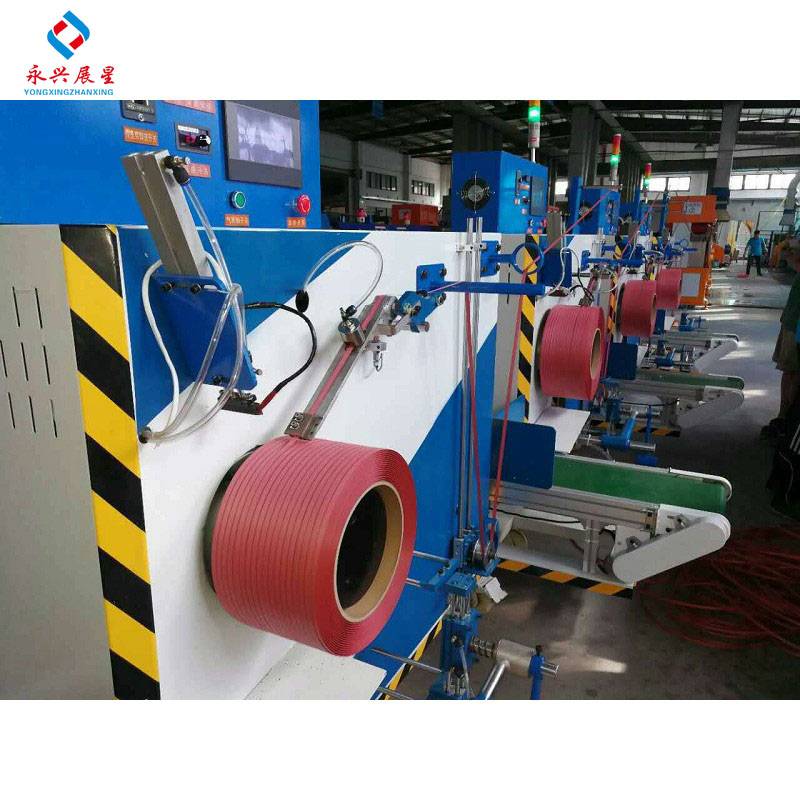

Machine features:

Solved the initial 1-2kg unstable problem cause by manual winding

Solved the high relying on worker’s experience

Greatly reduced the defected rolls

The finished rolls’ appearance size is the same, more neat and tidy

One worker can handle complete line, no mater it’s 2 strand or 8

Can calculate straps base on meters or weight , 2 options

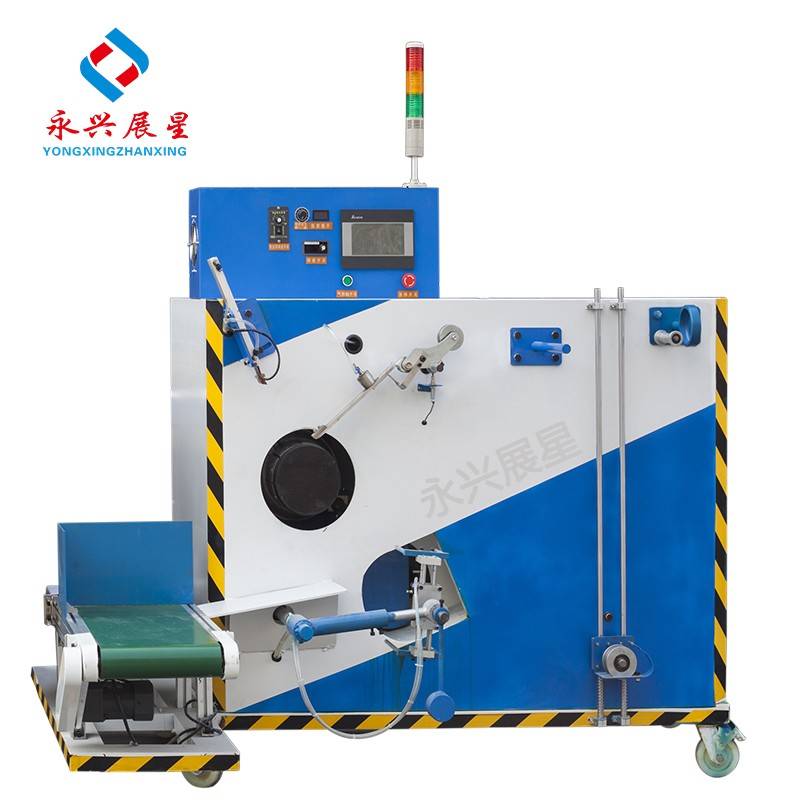

Technical parameters:

|

Model No. |

Z1070 |

|

Description |

Full Automatic Winder Machine |

|

Power |

2.0KW |

|

Strap Width Range |

5-19MM |

|

Paper Core size |

Ø200*H190mm ( Or Customize) |

|

PLC control system |

servo motor and PLC touch screen(DELTA) |

|

Weight |

450KG |

|

Size(MM) |

1950L*1500W*2000H |

Product detail pictures:

Related Product Guide:

IoT Strategy Cuts Human Error at Teel : Plastics Technology | Extruder For Plastic Granules

Live from Bulgaria: World Environment Day • Recycling International | Extruder Machine For Pp Rope

All we do is often involved with our tenet " Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for factory low price Reel Winder Machine - 2019 wholesale price Doubling Assemble Winding Machines Before Yarn Twisting Using – Yong Xing Zhan Xing , The product will supply to all over the world, such as: UK , Belarus , Barbados , Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.