Welcome to our websites!

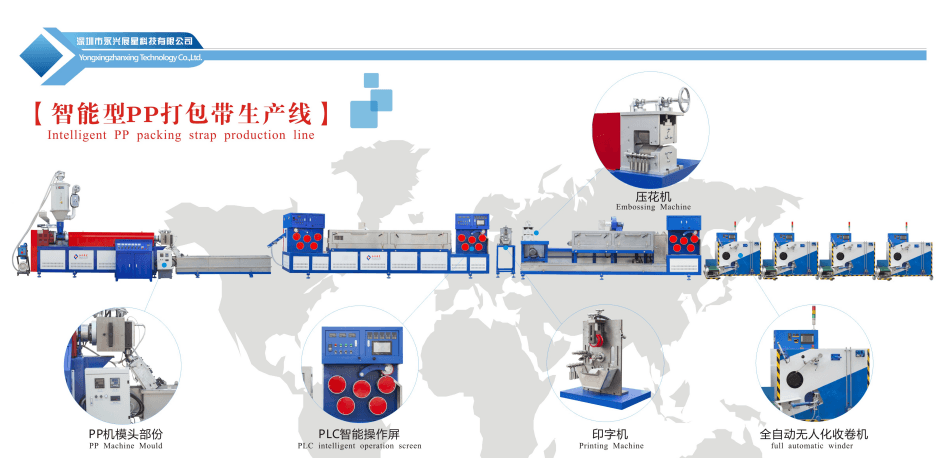

OEM/ODM Supplier Belt Plastic Machinery - PP Full Automatic Winder Machine – Yong Xing Zhan Xing

OEM/ODM Supplier Belt Plastic Machinery - PP Full Automatic Winder Machine – Yong Xing Zhan Xing Detail:

Machine features:

Solved the initial 1-2kg unstable problem cause by manual winding

Solved the high relying on worker’s experience

Greatly reduced the defected rolls

The finished rolls’ appearance size is the same, more neat and tidy

One worker can handle complete line, no mater it’s 2 strand or 8

Can calculate straps base on meters or weight , 2 options

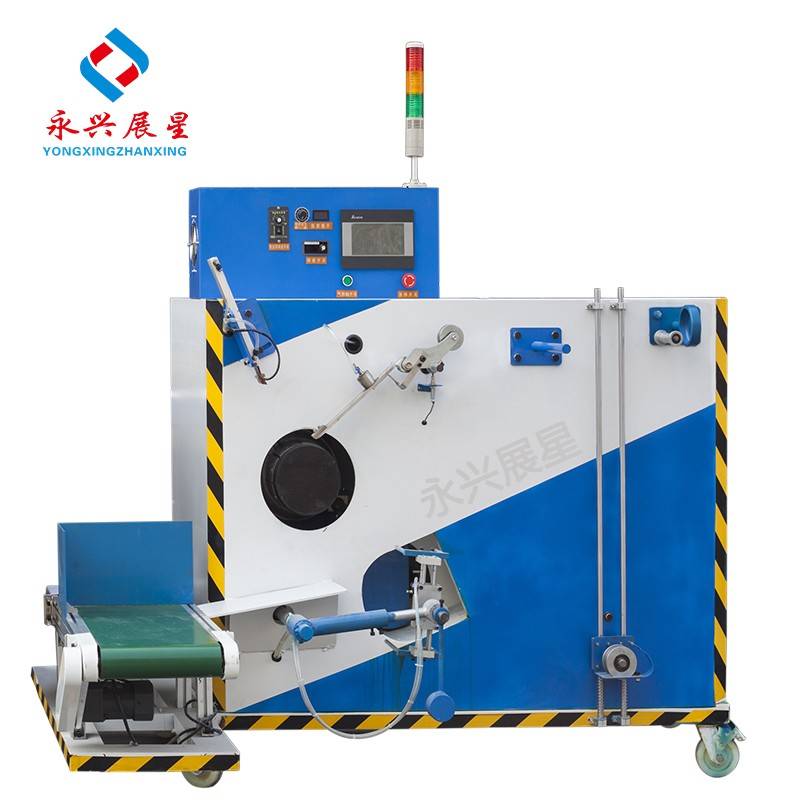

Technical parameters:

|

Model No. |

Z1070 |

|

Description |

Full Automatic Winder Machine |

|

Power |

2.0KW |

|

Strap Width Range |

5-19MM |

|

Paper Core size |

Ø200*H190mm ( Or Customize) |

|

PLC control system |

servo motor and PLC touch screen(DELTA) |

|

Weight |

450KG |

|

Size(MM) |

1950L*1500W*2000H |

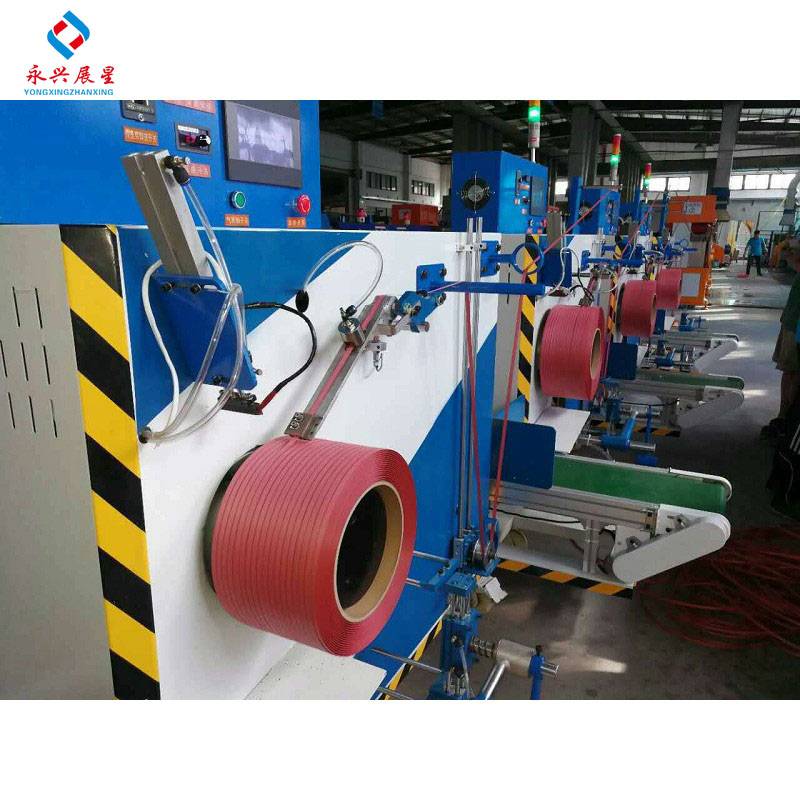

Product detail pictures:

Related Product Guide:

Live from Bulgaria: World Environment Day • Recycling International | Extruder Machine For Pp Rope

The Cheesecake Factory Bakery | Pet Packing Strip Extrusion Machine

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for OEM/ODM Supplier Belt Plastic Machinery - PP Full Automatic Winder Machine – Yong Xing Zhan Xing , The product will supply to all over the world, such as: kazakhstan , Philadelphia , Brunei , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.

Write your message here and send it to us